Stable Fuel Costs

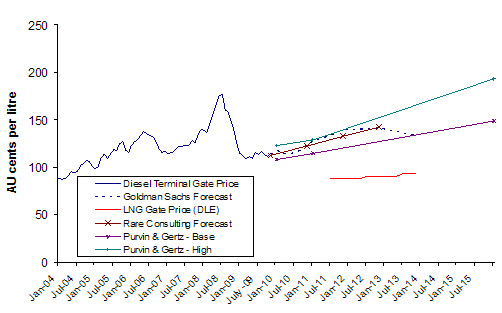

Unlike the price of diesel which is linked to the ever-volatile oil market, the price of LNG is much more stable, which allows for more control in business budgeting. See the graph below which demonstrates the volatility of diesel as compared to LNG.

Lower Price of LNG

LNG is lighter than diesel and therefore requires approximately 1.7 litres of LNG to substitute a litre of diesel. However, the significantly lower price of LNG means it delivers substantial annual fuel savings.

Longevity of Supply

Australia has abundant supplies of natural gas and it is expected that there are supplies of 80-100 years, or more, given projected demand.

Domestic Supply

In the near future it is expected that 80% of diesel supplies will have to be imported, which means reliance on the international oil market, whereas Australia’s natural gas reserves ensure local supply and freedom from international issues.

Extended Life of Vehicle

As LNG is a clean, non toxic substance it can extend the life of the vehicle for up to 3 times longer than a diesel engine. Additionally LNG-fuelled vehicles require much less servicing.

Reduced Noise Pollution

Vehicles running on LNG are far less noisy than conventional diesel engines. The LNG reduces vehicle knock.

Fewer CO2 Emissions

Depending on the type of engine, heavy duty vehicles running on LNG produce up to 20-25% fewer greenhouse gas emissions than diesel powered vehicles.

Improved Air Quality

Natural gas is the cleanest-burning fossil fuel, therefore vehicles running on LNG produce lower levels of toxic emissions and air pollution than equivalent diesel engines. Nitrogen Oxides (NOx) emissions are reduced by 40-50% and Particulate Matter (PM) emissions are reduced by approx 80%.

Time to Refuel

Refuelling LNG is just like filling up at a regular service station and the time taken to refuel an LNG vehicle takes no longer than filling a diesel one.

Safe to Use

LNG is harder to ignite than diesel and is less of a fire hazard than many commonly-used fuels. LNG is not held under pressure which greatly reduces the likelihood of explosions. LNG is non toxic and non corrosive and will not pollute land or water resources in the event of a leak into the environment.

Flexibility in Transport Routes

Unlike Compressed Natural Gas, which needs to be located next to a natural gas pipeline, LNG refuelling sites can be located anywhere, which means that there is flexibility over the expansion of transport routes for heavy duty LNG-powered vehicles.